Optimize Your Compressed Air System With Better Efficiency

Air compressor is a popular and most-expensive utility in the industrial plant. If you want super efficiency, compressed air is a poor option to transmit energy to a machine or tool. Here, Compressed air system manufactures will optimize the compressed air system to increase its efficiency. Moreover in emirates like Dubai, compressed air system will never disappear from the industrial plants since it’s a useful utility. Compressed air system manufactures in Dubai follow these steps to optimize the energy spent on air compressors,

- Conduct leak test

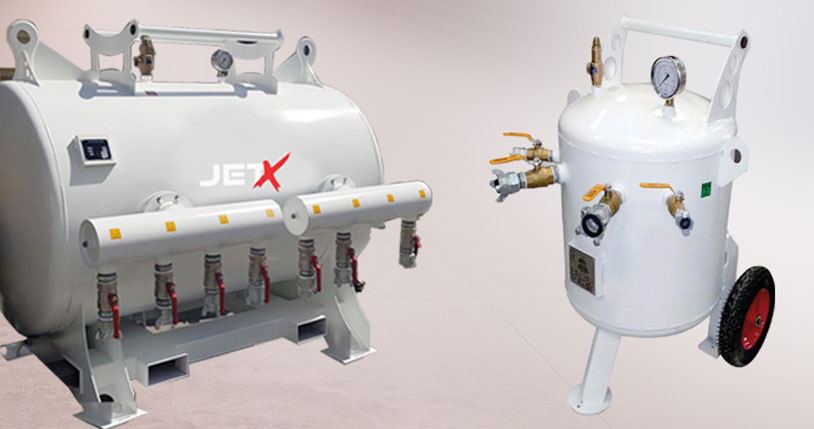

Air receiver tank manufacturers are completely aware of the air compressor system and conduct a leak test to identify its efficiency. If suppose your plant has non- continuous operation, then observe the loading and unloading times when there is no activity.

- Review air pressure requirements

The typical air compressor system pressure is around 100pisg. But, you may be surprised to know the fact that highest air pressure most users require is around 60 pisg. Therefore, it’s possible to reduce the air system to decent levels. While reducing the delivery pressure to 80pisg, it cuts down the power consumption by 9.5%. Additionally, it decreases the amount of air leaks and maintenance cost of compressor.

- Evaluate the air system components

Air receiver tank manufacturers check for the receivers’ size and location, size of distributing pipe, and type of the installed air dryer. When you include simple changes like adding receivers at specific locations and changing pipe’s size may reduce the air system pressure. Furthermore, review each type of air dryer used in the system because each has a certain amount of air loss and check whether you could replace if any.

- Assess the cooling system

If suppose your plant is located in the tropical region, it’s better to switch from air-cooled compressors to water cooling, Consequently, recover the heat of compression from preheating make-up water to boilers.

- Get enough training

While handling the compressed air system, make sure that you or your employees won’t get hurt in any way. We always see a surprised look on people when they discover the costs to run a compressed air system. Initially, basic knowledge on compressed air system is the first step to optimize your system and understand its efficiency. This keeps your costs in line.

- Boost efficiency with equipment replacement

While handling your compressed air industry in Dubai, it’s significant to know that customers are interested in energy efficiency as well. When you work on a expensive overhaul on old air compressors, make sure it doesn’t meet up with the present standards. Rather than spending time on an old air compressor, it’s better to replace the equipment with brand new efficient unit. Such replacements can reduce the operating cost within a short period of time.

- Reduce inappropriate uses

While optimizing the compressed air system, the inappropriate use of compressed air system is identified and analyzed during the research phase. Certain compressed air powered activities can be efficiently achieved using various other energy sources, some include pumping, cleaning, cooling, blowing, creating vacuum, and more.

Apart from the above listed optimizing techniques, Compressed air system manufactures use several other opportunities to reduce the cost of air compressor system. However, these steps could provide a good start towards optimization.

Fore more read about: air receiver tank manufacturers in dubai