How Choosing the Right Steel Shot Balance Increase...

19 Nov 2025

Nov

2021

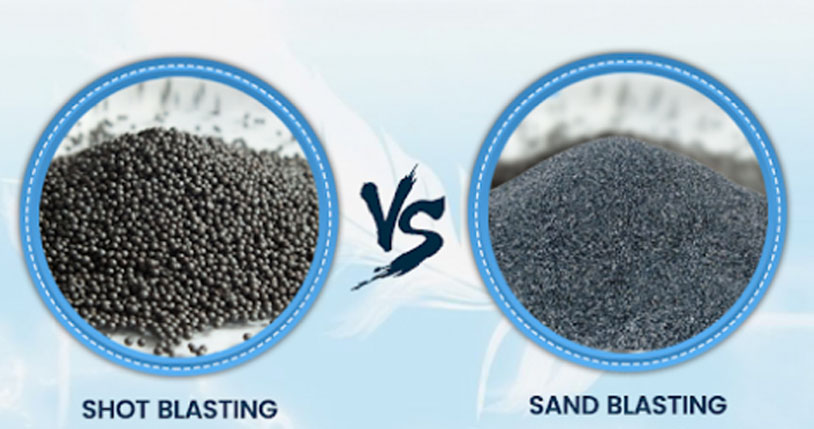

Abrasive blast cleaning is a popular industrial cleaning method in Dubai. The blast cleaning includes a powerful stream of abrasive material that forcefully breakdown into the superficial layer, this reveals the clean layer underneath. This cleaning method has gained popularity in Dubai and all over UAE in the past few decades, thereby giving rise to sub-services that engage in cleaning with various materials or techniques. Sandblasting and shot blasting are the popular abrasive cleaning methods.

Analyze the difference between the two methods and choose the right one!

Earlier, sand was the abrasive used in sandblasting but over time, sand had various issues like moisture content, contaminants, and more. Eventually, sand was diminished off, and sandblasting machine manufacturer use alternate abrasives for cleaning.

Now, the term sandblasting refers to the process of driving that abrasive material with the effect of compressed air. In this cleaning procedure, compressed air is the main source that directs a high pressure of abrasive media on the given surface.

For example – it can be an automobile part with grease, dirt, and oil or rusty chains in shipyard or old filing cabinets prepped for powder coating.

Sandblaster booth in Dubai works like a cleaning booth with all the required equipment to serve various industries. This proven pre-finishing technique has been around for years. The equipment has a free-spraying stream creating harmful dust clouds for a sophisticated enclosure with stream control options. Now, the media has changed from deadly sand to more user-friendly materials.

Despite the change in material and equipment, sandblasting is the common abrasive treatment for cleaning. It’s a suitable choice for soft and sensitive materials that are ready for final finishes. Sandblasting is more economical, affordable, easy to operate, and offers excellent quality.

Shot blasting uses a centrifugal or mechanical force that shoots out a swift stream of abrasive material at a surface. The force is achieved from a rotating turbine wheel. The abrasive materials used in shot blasting differ according to the target surface and nature of the project.

In most cases, industries prefer steel, whereas glass, aluminum oxide, or plastic materials are used for shot blasting. As per the results, shot blasting in Dubai is an ideal choice for cleaning steel or other ferrous metal surfaces.

Shot blasting is quite aggressive than sandblasting technique. In most cases, it’s used for large and complex projects that require strong application force and dense material to clean or prepare the surface.

It’s a basic method in large-scale operations, for example – restoring automobile frames, recycling steel containers, and more.

It’s a great dilemma while answering this question whether to consider sandblast or shot blasting? You have to consider several factors before involving in the abrasive blasting treatment. Moreover, the best method depends on the treating surface and expected finish.

Both the systems employ simple and advanced designs for quick cleaning. However, both system requires abrasive material and this material is the sole ingredient in this blasting process. The media is available in different forms based on the intended applications.

Sand blasting machine manufacturer may guide you on choosing what system and media to work on your specific project. Find professional blasting operations in Dubai for high-quality services.

19 Nov 2025

13 Nov 2025

03 Nov 2025

29 Oct 2025

03 Oct 2025